BEFORE I START, DO NOT TRY THIS WITH AN AC WELDER!!!!

For the past weeks, Ive been considering and designing for ultimately going to LiFePo4 (Lithium) batteries. One of the biggest hurdles I have found is finding not only a high amperage backup charger, but also one that I can get data from for my control system. As it stands my MPPT has all the charge and condition data I need on my batteries. With this not only can I see current state, but also trending of (at the moment) solar input and battery voltage over time. These are the only two parameters I care about at the moment.

I happened to be browsing Quora today and came across this

question. In it they ask about using the output from a welder as the input to an MPPT. Ive done some experiments with a converted alternator, bypassing the voltage regulator and using a larger external 3 phase rectifier. With that I would then vary the field to control power output. This was a pain but it worked. My issue is that I have this nice 3 Kw military diesel generator already. Problem is last time I put a charger on it, the charger failed. After this I went back to the engine driven alternator experiment.

Seeing the post linked above and having "napped" on the subject, I realized I have all the pieces to throw together a test. I have a Miller 152

DC (DO NOT CONNECT AN AC WELDER TO AN MPPT!) old model inverter stick / TIG welder. I also have a spare MPPT from my tests with the alternator. Well after tossing it around in my mind, I decided to setup for a test.

I dialed it in to 40 amps and checked the output voltage. ~88 volts DC was what I got, well within the spec of the MPPT (which is around 125 vdc, 40 amps or total (I think) 1050 watts) and within the continuous rating of the welder. I then wired the "welding leads" into the MPPT. I threw the switch. What I saw was nothing short of worth breaking out the Champagne!

The MPPT was staging and dumping 1087 watts of power into the batteries at 28.88 volts (equalize stage). Best of all, there was no undue heating of the batteries nor of the MPPT. Best of all, the "magic smoke" stayed inside all of the electronics!

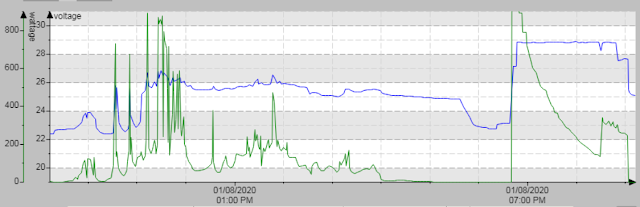

Next to see what actually happened. this is the chart of the whole experience

In the chart, blue represents the battery voltage. The line where it starts is 25 volts (had decent sun today). The green line is the input wattage. it is 0-900 in 100 watt increments. As you might guess, I was at first a bit dissapointed at the output. Then I remembered that the batteries were already at full charge (or close). The first "dip" was from turning on the washer and oil filled heater. The welder was easily powering everything and not putting power to the batteries. With the second dip, I had shut off the welder to let the batteries draw down from the heater. Keep in mind my batteries only have about 20% life left in them so it didnt take long to dip down to 22 volts under the load.

After discharging the batteries some, I fired the welder back up. Note that it immediately went to full power to the batteries to bring them back up. As they were taking charge, you can see the wattage (green line) dropping off as the internal resistance of the batteries increases. Being dark out and running out of time, I went ahead and shut things down having proven it will work.

My next test is to do it over about an hour or two. During this, I will know more about heating and how the whole system reacts under real world conditions. At this point I am confident it can be done without damaging anything. The only real question I have is if the welder will "throttle back"far enough so as not to require a dump load. The basic principle has been proven to my satisfaction, now its just "details".

Addendum 1-3-2020

Today I did a more thorough test. This time I ran for about 7 hours. I couldnt be more pleased with the results

Nice clean charge with the wattage tapering off just fine. At the end of the run I was up to about 93 volts going in and around 100 watts. I also bought a contactless thermometer and noticed nothing unusual with the batteries running at around ambient temperature. The MPPT was running about 72 degrees at its hottest point. At this point, I consider the results better than even what I got out of my original grid connected charger.

I cant comment on other combinations, but I now know my welder with my MPPT has been a complete success. Next to test the welder with the generator, but that is an unrelated subject. If that works I then have a portable welder that I can also use as a backup charger around the homestead.

Addendum 1-4-2020, The Welder and MPPT

Some have wondered about the methodology I used to determine if or how this was going to have a good chance of working. Here I will review a bit about what I checked first before I even connected the wires.

The MPPT

In my system I am running an

Epever 4250BN MPPT. Now to me the datasheet is a bit confusing. Some of the ratings just dont add up. Because of this I went with the lowest individual rating values. First of all we have different values based on the battery voltage. This tells me that the MPPT finds current (amperage) as the most important value. This you can see in my other posting about "Amps,Volts, and Watts". Long story short, the electronics care more about the current passing through (wire and electronics sizing) than the voltages. My battery pack and inverter is 24 volts (in my opinion the minimum voltage for a serious system). So now to look at the datasheet....

- Rated charge current 40 amps (discharge @20 amp I believe is for the dump load)

- Maximum PV input power 1040 watts. This is what your welder should be set to supply as maximum.

- Maximum input voltage 138 vdc. (for some reason this is not on the datasheet but in the amazon ad).

It should be noted that I monitor my values from the data bus of the MPPT. You can get approximate values during setup and test with a volt meter and a DC clamp on amp meter. NOTE: not all clamp on meters will do DC. If you are doing a solar system, a DC clamp on amp meter is a MUST in my opinion. Do not use your normal meter in "amps" as most are fused to around 10 amps. A clamp on will take you into the 100's of amps.

The Welder

Next, I look at the data sheet for the

welder in question. In my case it is a Miller 152 Maxstar. Everything you need to know is on page 9 (in my case). Here we find

- 100% duty cycle (meaning it can run continuous) of 125a at 25vdc.

- Open circuit voltage 95vdc. This is the "no load voltage" verified with my meter.

Next we look at the volt-amp curve. This one is very important. Remember as you draw more amperage the voltage will drop. For the test, I set my current limit to ~40 amps on the welder so as not to accidentally overload the MPPT.

Looking at the output curve, at 40 amps the voltage will drop to about 65 volts. This is still well within the spec for the MPPT. The maximum I saw during my testing on flat batteries was 73.78 volts at 14.74 amps, for 1087 watts. This is slightly above maximum for the MPPT but it was not significantly over rated. I suspect the MPPT was burning some of this off as heat. If I had run at that wattage for a longer period of time, I would have first tried turning down the amperage setting a bit. NOTE: I do NOT know this for a FACT!

Other DC Inverter welders

I just finished searching for other welders of this type. Nowhere could I find a detailed volt/amp curve for the welder in question. I did find some that listed their open circuit voltage. This was usually around 70vdc. The other thing you need to know which I couldnt find is the "duty cycle" at the amperage you need.

What the duty cycle is (in case you dont know) is how long you can power at a given amperage before the machine needs to cool down. Some of what I saw was listed at 75 amps but a 20% duty cycle. What this essentially means is you can run at 75 amps for 2 minutes and then the machine needs to cool for 8 minutes (roughly). All I will say without having the actual data is firstly this is not a "linear value". In other words 37.5 amps will not necessarily give you a 40% duty cycle.

Personally, I wouldnt look at anything below 150 amps or so rating. After all, you may want to also use it as a welder. Most serious welding work is going to happen in the 80-120 amp range.

Update 1-6-2020

My new welder / charger just arrived. I purchased a cheap one off of

Amazon. It is a 110/220 vac inverter type. Other than a little lower voltage running on 120vac vs 240vac of the Miller, there was no difference in performance in initial testing.

The only issue I did see is I had paralleled 2 40a MPPTs last night in preparation. One is on the panels (900 watts) and the other on the welder. Both were connected to the same batteries on the output. There seemed to be some "contention" over which MPPT was going to "run the show" (after a good day of sun).

Despite that minor issue, no magic smoke was released and everything returned to normal when I isolated the input of one or the other. One very pleasant surprise was the power draw of the welder. My previous dedicated charger would pull close to 15+ amps to charge batteries directly. With this method it was pulling only around 9 amps for the same power. In this regard the welder is MUCH more efficient.

Final Thoughts

In todays installment, I pulled my batteries down heavy before starting. I did see the input wattage to the MPPT peak up around 1100 watts for a while. This isnt all that much above MPPT spec. On the other hand it does make me think that the security of having a dump load would be worth the minor expense. Since I dont have a dump load, I cannot tell for sure. Dialing down welder amperage didnt seem to have a lot of effect (neither did dialing it up for that matter) on anything other than voltage.

This gives me an educated guess that the MPPT will only take what it can use off of the welder (MPPT regulating the overall charge side). I did notice some heating (76 deg/f with ambient being around 60 deg/f) of the MPPT. Note that the MPPT does have overtemp protection with shutdown around 150 deg/F.

After testing with another DC inverter welder and 2

40a MPPTs in parallel and seeing the contention between MPPT's, I think I will end up making a minor change to the overall plan. I will go back to one MPPT of higher output capacity with a source

transfer switch on the input. I will then set it up so that it is "motorized" for remote switchover. I know I could use relays or contactors but I dont want to waste the power on holding contactors and cant find anything high amperage that is latching.

All in all, I stand by my initial overall conclusions.